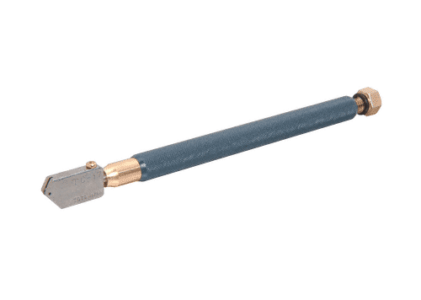

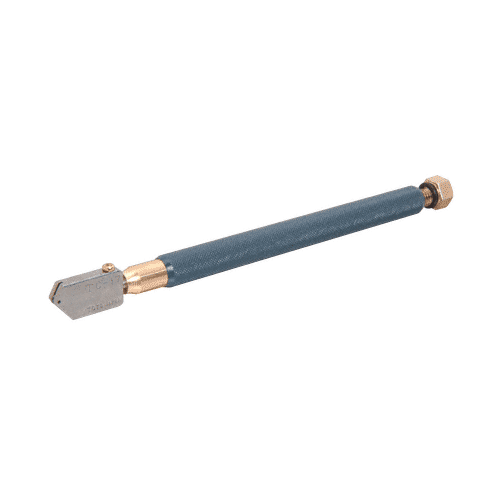

I did a lot of research before getting a glass cutter. Hands down after my research was Toyo cutters. Then it was just the grip style. I have used pistol grip when I work on fused glass at a studio up in Door County. I do prefer though the pen/pencil style of cutter. I have purcahsed the Toyo TC17B Original Supercutter Brass Handle Straight Head Oil Cutter. This cutter has treated me well for the last 5 years without issues. Always have oil in the body that feeds the cutting head and regular cleaning will give you very long life on the cutting head.

The top of the cutter screws off to put cutting oil in it. I put in a few drops. The body does not need to be filled with oil, a little will go a long way. Cleaning the cutting head is pretty easy. At the end of every project I will wipe down the entire cutter and then with a small pipe cleaner I will feed it through the cutting wheel and frame to clean out and glass bits that may have gotten stuck due to the oil pathway from the cutter body.

Not too much pressure is needed. There is a spring in the cutter that gives an indication of how much pressure is needed. You just need to apply enough pressure to compress the spring to cut but the glass. The noise when cutting glass, depending on glass, will be no noise to a paper ripping noise. When you do hear the paper ripping noise this should be heard for the entire cut of the glass. If there is no noise, there should still be a line on the glass where the cutter passed. Too much pressure will cause the glass to shatter.

If you are new to glass cutting, get some cheap or scrape glass to practice your cutting. Patience and practice is what is needed for cutting glass and overall with this art form.